When investing in a luxury fishing boat, you want a boat that features the most sophisticated build techniques and engineering. You want the best. Thanks to our meticulous build process, Scout creates some of the most superior sportfish boats on the water.

Here are a few techniques we use to create the perfect fishing boat for you and your family.

In-House Research and Development

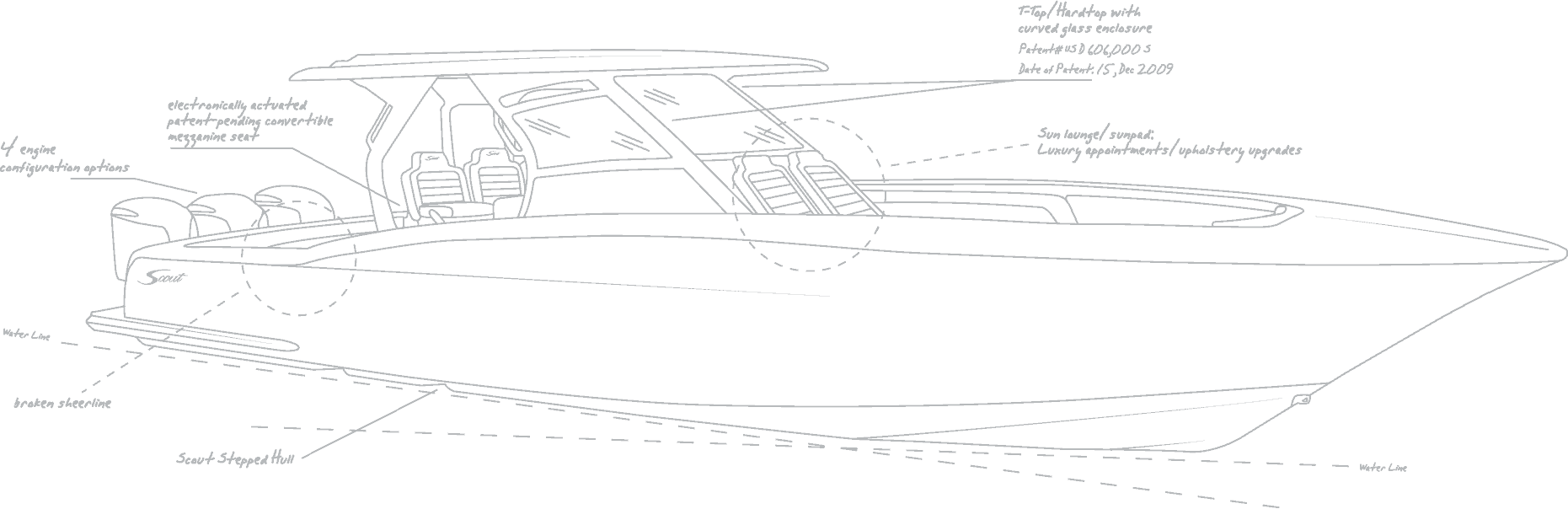

Every Scout boat is researched and designed in-house by our experts. Many boat companies outsource their research and development process, allowing other teams to design and create themes for their boats. Scout, however, takes a proactive approach to research and development, using our own design team and engineers to create the perfect boat. We are developing 4 to 6 new models at all times, allowing us to stay at the forefront of boat innovation and design. Conducting our research and development in-house means you get a more unique boat and a superior design.

Precise Laminate Schedule

Scout boats are built to perfect consistency using what we refer to as our “Laminate Schedule.” This process allows our engineers to assemble the fiberglass pieces in the boat the same way, every time. Our laminate schedule lets engineers determine the thickness of the boat, and is one step towards perfect consistency. The fiberglass material is rolled out on a cutting table, and templates are used to cut the precise piece. The pieces of fiberglass are then put together like a puzzle to create the perfect boat, every time. Thanks to our laminate schedule, every Scout boat arrives with the most accurate consistency possible.

Hand-Laid Construction

Another important aspect of our boat-building process is the 100% hand-laid construction. Every part, including the hulls, consoles, decks, boxes, and more, are all hand-laid by our team. Materials are cut to a specific pattern to ensure consistency, with no variation between boats of the same model. Our 100% hand-laid process means a better strength-to-weight ratio. Our boats are faster and more efficient while still maintaining excellent strength for years.

Thorough Tabbing

The tabbing department at Scout boats works on connecting the bottom of the deck with different parts, including live-wells and anchor boxes. Because some parts have different shapes and angles, they can’t come out of the mold at one time and have to be molded separately. This creates the need for a strong attachment that is water-tight and will last for years. Enter the tabbing department. Our tabbing is done with fiberglass to create the perfect seal, and this process is done on all of our boats ranging from 15 feet to 42 feet. It creates a better, longer-lasting waterproof seal between every part, and ensures a higher quality for your boat.

Scout: Leading the Way in Boat Construction

Scout is proud to create some of the most advanced and sophisticated luxury fishing boats on the water. With innovative designs and a thorough build process, Scout is the leader in quality, efficiency, and comfort.

Contact us today to learn more about advanced Scout boats, or browse our different models to find the right fishing boat for you and your family.